You may not be able to do that kind of incremental summation or something. Then we scan through the snapshots table, add data files one by one to this new ICDC table. Of course, this code is simple and it’s not like a full production, but it demonstrates the idea clearly. You might consider a similar approach in your solution if applicable. The key is that the event time matters a lot to the business, not the processing time.

- Here I have this simple table called db1, table 1, at workload time, T1.

- Conversely, fixed costs, such as rent and overhead, are omitted from incremental cost analysis because these costs typically don’t change with production volumes.

- Also, because this runs so fast, we can be doing this hourly instead of daily.

- We even don’t need to create a table, instead we just need to get the upper and lower bound of some specific change columns from the source tables.

- By knowing how costs will change as production volume changes, a company can make more informed decisions.

- As a third example, the sale of a subsidiary includes the legal costs of the sale.

How do you calculate the incremental cost at different scales of production?

If we look at our above example, the primary user is product ‘X’ which was already being manufactured at the plant and utilizing the machinery and equipment. The new product only added some extra cost to define ‘X’ as the primary user incremental cost and ‘Y’ as the incremental user. Then, in this auto remediation approach, you’re just doing the same thing in this type of flow that either cause this typical ETL pipeline plus auditing process. Then, they can tell Maestro, if this subworkflow failed, please don’t fail the workflow and page me, please just ignore that first and then run a recovery job. Incremental costs are also referred to as marginal costs, but there are some basic differences between them. This check status job will see if actually subworkflow failed or not.

- The first section, like description section, that the user can put some information, even some on-call instruction there.

- Then this final pipeline will be based on the range captured, here it is min of 3 and max is 6, so that you are going to load the data from all three tables from hour 3 to hour 6 together.

- Then in the commit step, users just need to tell us what’s the step ID of the IpCapture.

- This way, companies develop a realistic production roadmap, with an exact number of goods to be produced and the pricing per unit, to achieve profit goals in a business quarter.

- Then a user can also use the UI to take a look at what’s wrong or what happens.

- Calculating incremental manufacturing cost can be complex due to the dynamic nature of production environments and the need for accurate data.

Variable Overhead

Assuming a manufacturing company, ABC Ltd. has a production unit where the cost incurred in making 100 units of a product X is ₹ 2,000. It also helps a firm decide whether to manufacture a good or purchase it elsewhere. There are some other alternatives to achieve a similar goal, to enable this incremental processing, using Iceberg, like Iceberg with Flink, with Spark Structure Streaming, and so on. We didn’t go with those approaches, mainly just because they are coupled with the engine tightly. The first step in calculating the incremental cost is determining how contribution margin many units you want to add to your normal production capacity. Incremental costs are also used in the management decision to make or buy a product.

Incremental cost and its effect on pricing

Economies of scale occur when increasing production leads to lower costs since the costs are spread out over a larger number of goods being produced. In other words, the average cost per unit declines as production increases. The fixed costs don’t usually change when incremental costs are added, meaning the cost of the equipment doesn’t fluctuate with production volumes. From the above information, we see that the incremental cost of manufacturing the additional 2,000 units (10,000 vs. 8,000) is $40,000 ($360,000 vs. $320,000). Therefore, for these 2,000 additional units, the incremental manufacturing cost per unit of product will be an average of $20 ($40,000 divided by 2,000 units). The reason for the relatively small incremental cost per unit is due to the cost behavior of Coffee Shop Accounting certain costs.

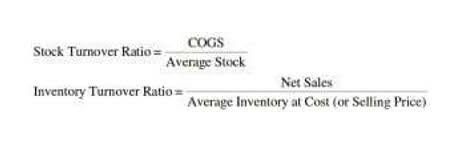

How to calculate Incremental Costs?

Like in the above example, it is evident that the per-unit cost of manufacturing the products has decreased from ₹ 20 to ₹ 17.5 after introducing the new product line. Identifying such costs is very important for companies as it helps them decide whether the additional cost is in their best interest. As a result, the total incremental cost to produce the additional 2,000 units is $30,000 or ($330,000 – $300,000). Then this final pipeline will be based on the range captured, here it is min of 3 and max is 6, so that you are going to load the data from all three tables from hour 3 to hour 6 together. Then doing the complicated join operations to produce data to the target table.